Technology Collaboration with German Edge Cloud

We are supporting German Edge Cloud in the development of their ONCITE Digital Production System suite by providing software components for 3D visualization, user interaction and other areas. Our contribution is bolstered by technical prowess and end-user-centric design sensibilities built up over years of AAA game development experience.

Our Contribution

We were approached by German Edge Cloud to participate in an on-going research collaboration to establish the viability of using game technology and a game presentation mindset for traditional software products.

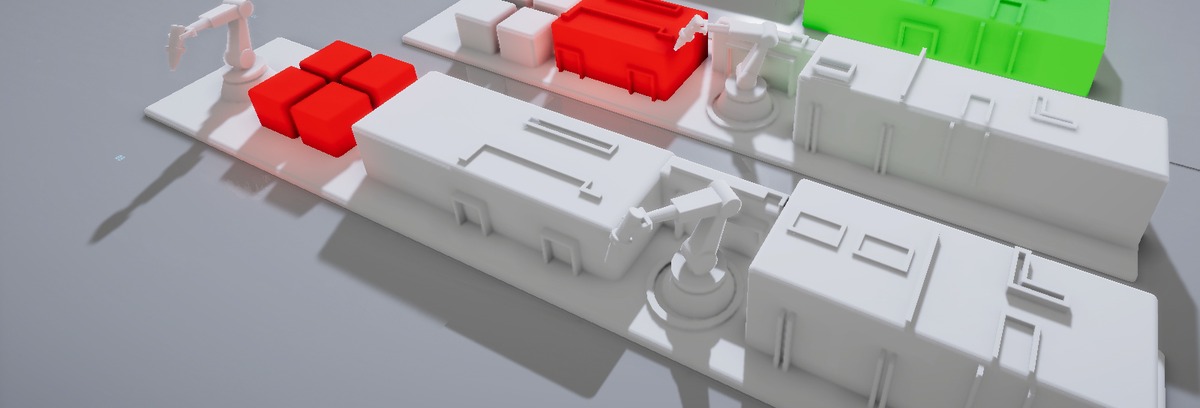

We developed visualization and interaction solutions to be used in the so-called Virtual Factory, a digital twin of an actual production facility - powered by large-scale sensor data collected, aggregated and served by German Edge Cloud. This is to aid not only in near real-time and historical monitoring but also facility layout and logistics planning.

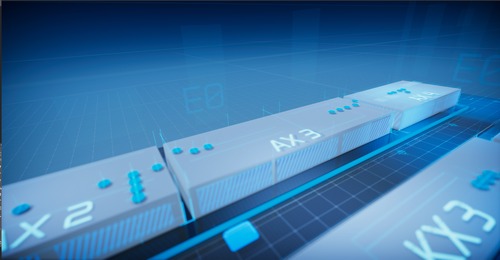

Our first goal was to develop a solution for rendering view ports of point clouds with several billion points and stream the rendered images or an interactive video stream to end user devices. We developed a high-performance point cloud rendering library for use with the Unity game engine. It reads the open data format established by the POTree research project and employs state of the art methods for removing point cloud scanning artifacts such as holes and stray points. This was rounded off by some shader tricks that allows the display of volumetric heat maps using the same point data.

On a separate track, we contributed to the project by designing and implementing a clean and pleasing visualization model for production plant dashboards. Our Unity-based solution serves rendered images of a facility overlaid with custom live metrics to information screens distributed throughout that same production plant.

Last but not least, our team implemented a Unity WebGL-based front-end that allows customers of the system to interactively develop three-dimensional floor plans of production plants in their browser, while still benefitting from a slick presentation and snappy interaction. Our rendering and simulation component is embedded into large scale web applications to visualize manufacturing logistics, information streams and even minute manufacturing processes. Using telemetry gathered by sensors in the live production facility, the movement of individual machine elements can be traced over time to optimize or troubleshoot complex processes with many moving parts.

All solutions we delivered satisfy elevated quality standards by means of automated unit-, integration-, fuzz- and smoke testing, following deployment and testing procedures developed by our in-house quality assurance department.

© German Edge Cloud